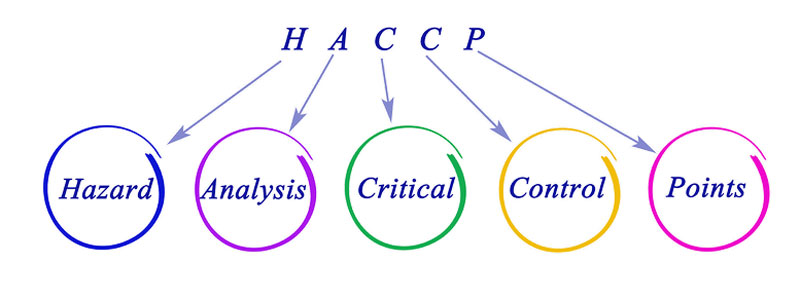

Hazard Analysis and Critical Control Points (HACCP) is a system that works to prevent contamination in the food industry and to ensure food safety. It is done in a way that is logical, objective and standardised from one industry to another. HACCP looks at physical, chemical and biological risks throughout all processes in the supply change. If there is a risk, HACCP will highlight this and a preventative measure is established to correct the problem.

The Importance of HACCP

A lot of people underestimate the importance of Hazard Analysis and Critical Control Points, even though it is a vital part of any aspect of food production. It doesn’t matter whether your business produces food or manufactures a material in contact with food, you need to consider the risks and what could go wrong in regards to food safety. This is also the case if your business is pharmaceutical or cosmetic, as there are risks to end users if certain precautions are not taken. Luckily, HACCP is there to ensure food safety is controlled.

HACCP is a management system that controls potential hazards in food production. It addresses food safety by analysing a wide range of hazards throughout the production process. This includes procurement, manufacturing, distribution and consumption. By controlling and monitoring major food risks, it’s easier to ensure products are safe. The HACCP system is used for food production, pharmaceutical production and the manufacturing of anything related to food consumption.

At Stop That Pest, we understand the importance of HACCP. Whether you are working in the food industry or pharmaceutical industry, or any other industry that manufactures materials in contact with food, you can benefit from our professional HACCP service. To find out more about Hazard Analysis and Critical Control Points, or any of our other services, get in touch with the helpful Stop That Pest team.